This may have some questions that many people are concerned about, what is a fiber optic cable splicer? How to splice optic fiber cable? How to repair a broken fiber optic cable? Why do fiber optic cable connectors have so many meanings and differences? Here, we share our experience and understanding with you.

What is a fiber optic cable splicer?

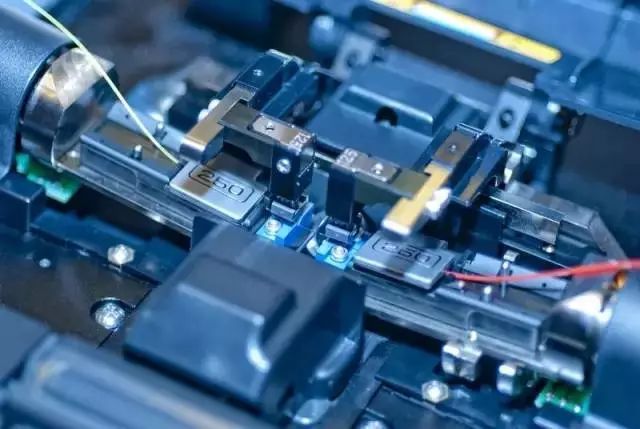

Unlike traditional communication cables, fiber optic cables are transmitted through optical fibers. Because of the very thin diameter of the optical bare fiber, for fiber optic cables, splicing requires a dedicated device. During the construction of fiber optic cables, the fiber optic cables delivered to the construction site are generally without connectors. Moreover, the delivery length of the general fiber optic cable is generally 2-4km in length. In many cases, the line length of the fiber optic cable cannot reach the designed transmission line length. The fusion splicing of optical fibers distinguishes between two methods, optical fiber fusion splicer fusion splicing and fusion splicing by using quick connectors.

Thermal fusion method of fiber optic cable splicer

This welding method is the method with the least attenuation, the highest efficiency, and the most applications. Whether it is the extension and splicing of the fiber optic cable or the repair of the broken fiber optic cable, the best way is to use the hot melt method to solve it.

In the construction process of the optical fiber cable fusion splicer, the following points should be paid attention to:

- Do not splicing in a humid and dusty working environment;

- Optical fiber cable fusion splicer, optical fiber cable breakpoints, optical fiber cable cutting tools, etc. must be kept clean;

- After the welding is completed, it is necessary to make corresponding physical protection for the welding point to prevent it from being broken during subsequent construction or laying;

- After welding, it is necessary to detect the loss of the welding point through the OTDR equipment to ensure that the attenuation of the welding point can reach the ideal value.

The use of fiber optic quick connectors

Using a quick coupler is an easy and fast way. Perhaps not many people own a fiber optic cable fusion splicer, and fiber optic quick connectors are another option. However, this method has an obvious disadvantage in that the attenuation of the connection point will be larger than the attenuation coefficient of the optical fiber fusion splicing. Therefore, the general optical fiber quick connector is suitable for the scenario of optical fiber transmission end such as fiber to the home. In an optical fiber transmission link, it is best not to have too many optical fiber quick connectors, which will affect the quality of signal transmission.

The difference and selection of the 4 commonly used fiber optic cable splices

About the SC Splices

This kind of connector, whether it is used as a fiber patch cord or pigtail, is a very wide choice. Its advantage is that it can be quickly connected to the device through a plastic clip. But this advantage can also be its disadvantage. Because there may be a certain numerical error in the snap, there may be a gap between the ceramic ferrule and the coupler or patch cord connector, resulting in increased attenuation.

About the FC Splices

The connection method of FC is mainly through the thread and groove inside the joint. This connection is more stable than SC. But because it needs to be fixed by internal threads, it will take a long time to install.

About the LC Splice

The LC connector can be seen as a reduced-size version of the SC. It is also fixed by clips, and its size is smaller, which is more suitable for use on SFP modules.

About the ST Splice

Likewise, ST can also be used as an optimization for FC linkers. It eliminates the structure of the internal thread and uses a screw buckle to connect. This way, it saves its installation time.