Indoor types of fiber optic cable also have many structures like outdoor fiber optic cables. They have more convenient and multi-functional use methods for different construction conditions. Before that, we shared a detailed analysis of outdoor optical cables. If you are interested, you can click the article link

<The Detailed distinction of Outdoor Types of Fiber Optic Cables> for an in-depth understanding.

Regular indoor types of fiber optic cable

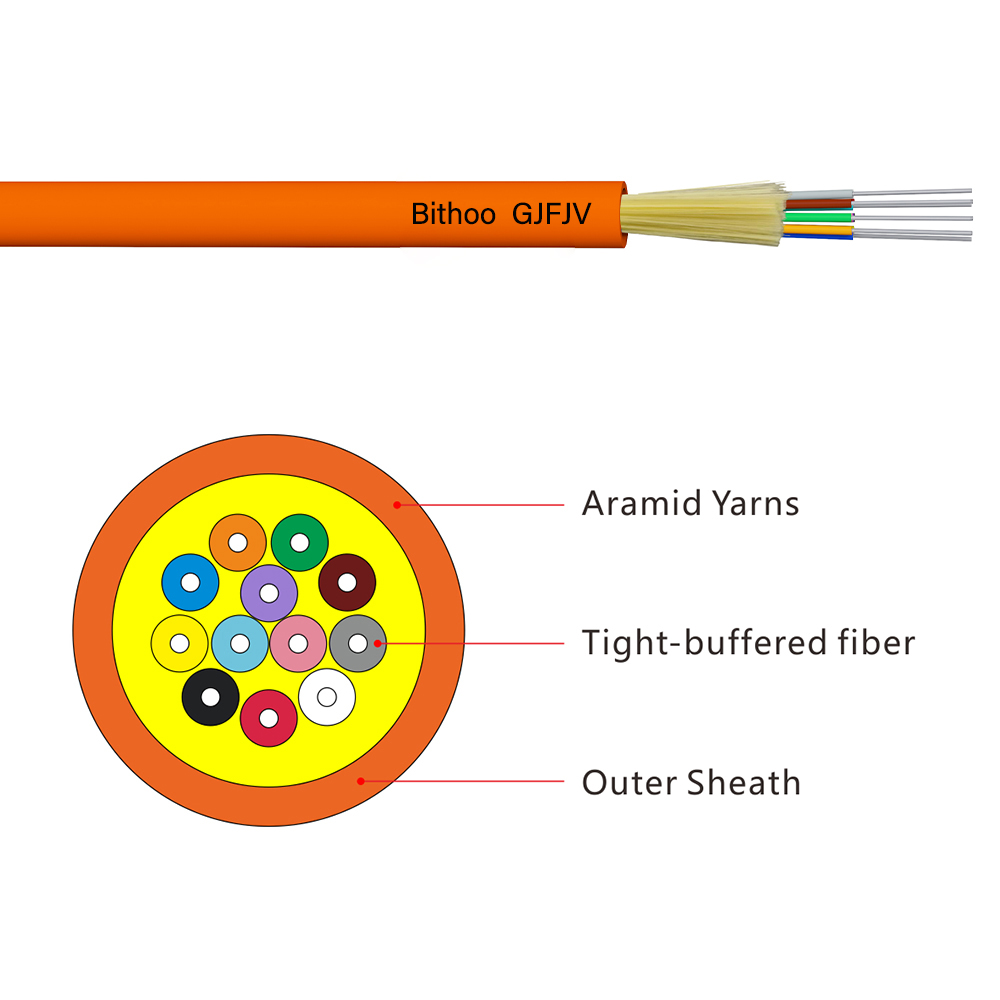

Different from various outdoor weather conditions, construction environment. The indoor environment is relatively mild. First of all, our starting point for the design of indoor fiber optic cables is to determine the number of optical fiber cores required by the optical fiber transmission system. Like in large office buildings or apartments, there will be fixed wiring pipes for cable laying. However, due to the complex corners and relatively small construction environment, the fiber optic cable is required to have a small volume, a lightweight, and excellent tensile and bending properties.

Usually, we recommend choosing the fiber optic cable of the GJFJV structure. Its interior is filled with aramid fiber, which has excellent tensile strength, and the tight-buffered fiber is easy to slide inside, so its bending performance is also very good. GJFJV is suitable for laying in complex indoor wiring pipes and wire grooves. Similarly, the outer sheath can be made of PVC material with flame retardant properties, which can prevent accidental fire accidents.

Fiber optic cable suitable for indoor overhead laying

In indoor construction without a wire trough environment, we will also encounter situations that require the overhead laying of fiber optic cables. In the outdoor fiber optic cable, we can have GYXTC8S and GYTC8A structures. In the indoor fiber optic cable, we also have a similar structure: GJFJTC8Y. Unlike the outdoor figure 8 fiber optic cable, we choose to use aramid fiber instead of steel wire rope. This makes the overall weight of the fiber optic cable lighter and easier to lay in the air.

Likewise, it can also choose a PVC outer jacket with flame retardant properties to prevent accidental fires.

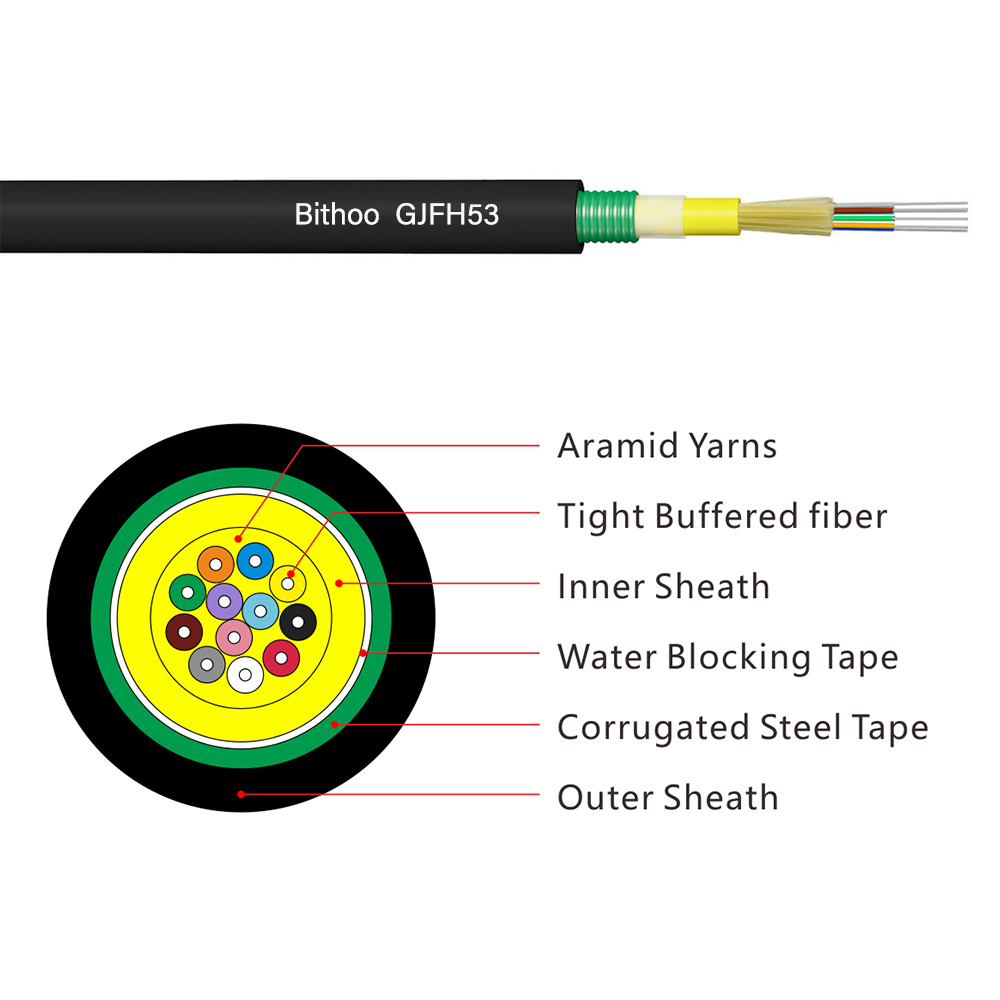

Indoor armored fiber optical cable

Of course, when armoring is also needed indoors. In some farms or warehouses, we have to face some bugs or mice. GJFJH53 is a very good solution. Its overall structure is like adding a layer of plastic-coated steel tape armor and a layer of the sheath to the outside of the GJFJV. The hard steel armor can effectively resist the bite of mice and insects. It also makes it have better impact resistance performance than other indoor optical cables. Although this will make it less bendy, we can also peel off the outer sheath of the armor and continue construction with the GJFJV inside. It also has a water-blocking tape, which is ideal for relatively harsh indoor installations.

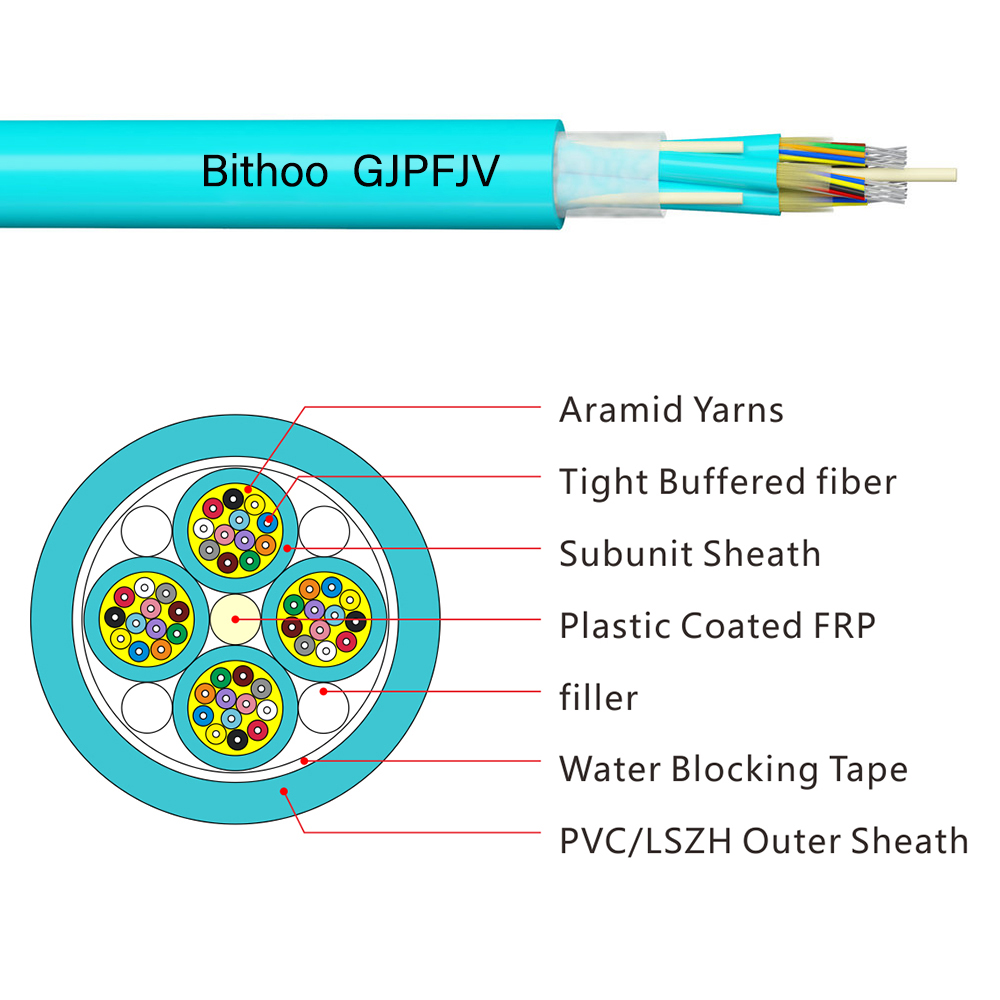

Backbone fiber optic cables for data centers

In the process of building a data center, fiber resources are the first consideration. A large number of switches and servers are erected between different cabinets, which makes GJFJHV and GJPFJV an excellent solution.

These two multi-purpose break-out fiber optic cables have an ingenious structure that is different from other fiber optic cables. Under the outer sheath, there are multiple sub-unit fiber optic cables. In addition to having more fiber cores, at the end of the backbone line, the outer jacket can be directly stripped, which allows the internal subunit cables to continue to be laid. The whole process does not need to cut the fiber optic cable, which makes the construction process more flexible.

Especially in outdoor multi-mode 10 Gigabit transmission lines with ultra-large bandwidth. The construction step of cutting the optical cable and then splicing is omitted, which will reduce the attenuation of the optical signal. This also makes GJFJHV and GJPFJV widely used in network construction.

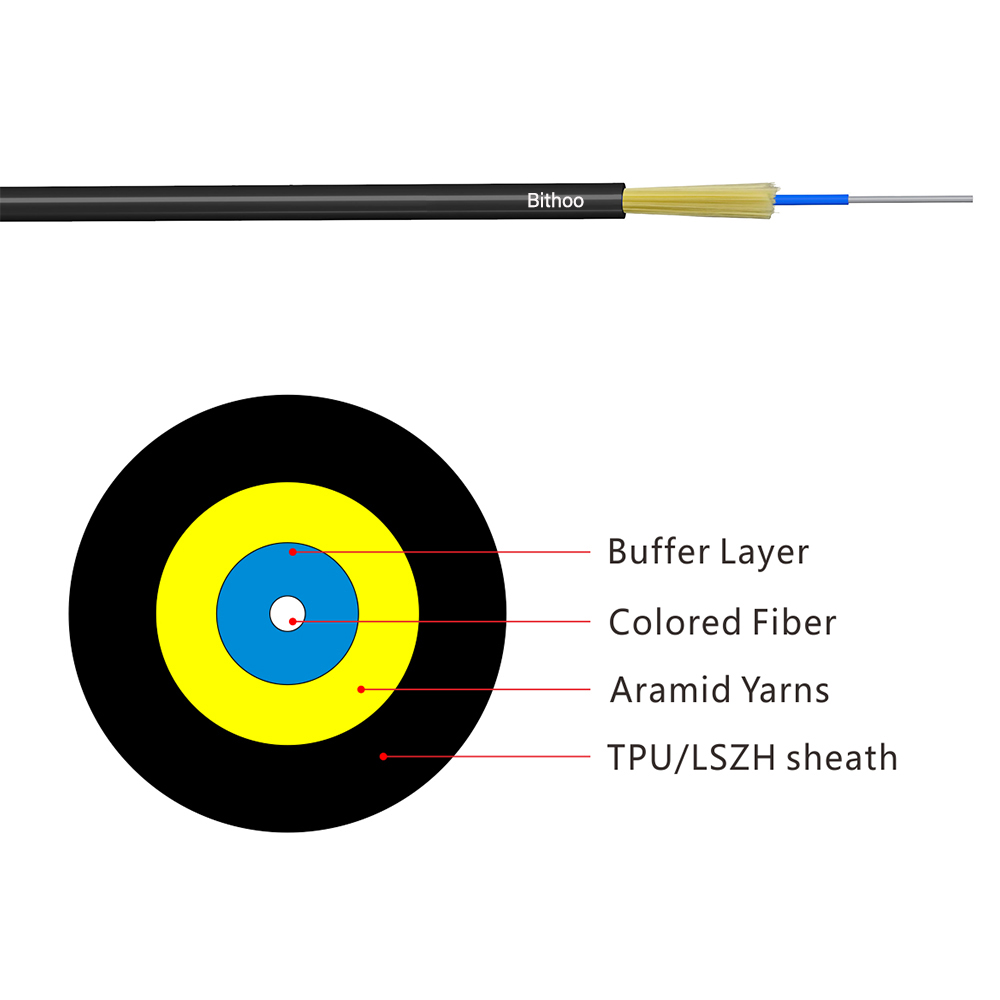

Temporary fiber optic cable

Sometimes, we will encounter some special situations. For example, such as temporarily erecting a test line. At these times, we may need a fiber optic cable that can be used temporarily, which can be stored for the next use after use. The tight buffered fiber optic cable is a good choice.

Its interior is also filled with aramid, which makes it have excellent bending properties and high tensile strength. The outer jacket of the fiber optic cable is made of TPU material, which makes it more wear-resistant. We will also equip it with a storage tray, which makes it easier to store optical cables.

Here, we introduce these commonly used optical cables, if you are interested in us, you can browse our official website: Bithoo communication. We are very willing to provide you with professional service.