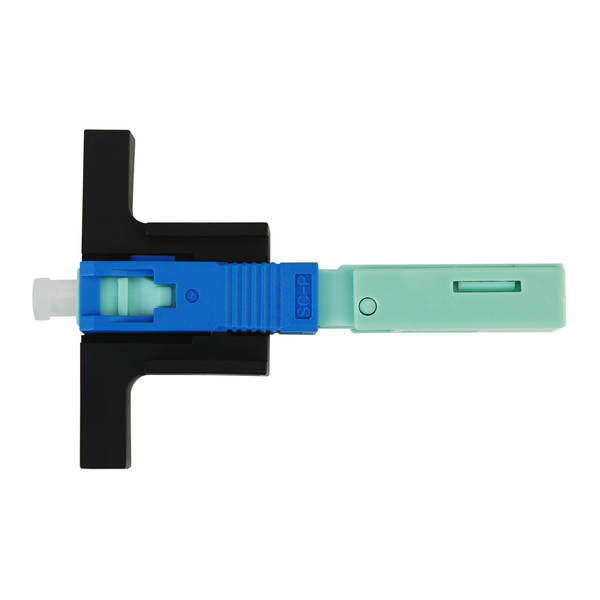

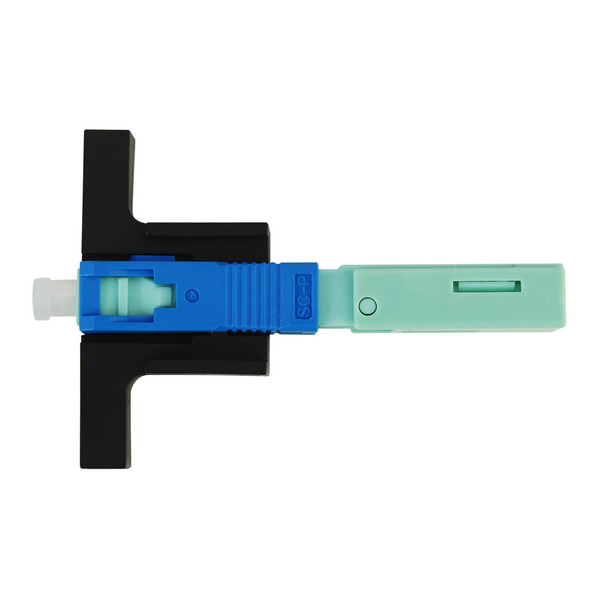

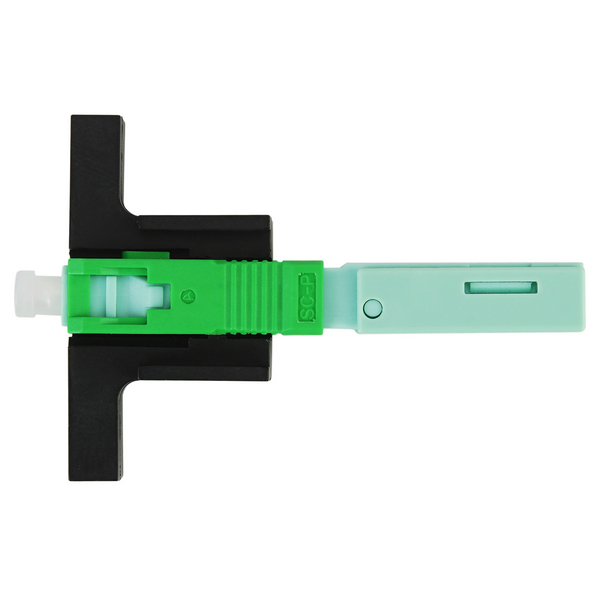

Optical Fiber Fast Connector Introduction

- 1. Applied to open FTTH fiber terminal optical fast connector

- 2. Used in closure boxes, cabinets, terminal boxes, couplers, etc.

- 3. Recovery and maintenance of fiber breakage and other accidents

- 4. LAN, WAN, data, and video transmission

- 5. Construction and maintenance of fiber access for end-users

- 6. Fiber entry for mobile base stations

- 7. Optical communication systems, optical instruments, optical fiber CATV, optical fiber sensors.

Product Standard

Comply with international standards:

1. ITU-T and IEC and China standards:

2.《YDT 2341.1-2011 Field Assembled Optical Fiber Active Connector

Part 1: Mechanical Type》

3.《China Telecom fast Connector Standard [2010] No. 953》

4.《01C GR-326-CORE (Issue 3, 1999) General requirements for

single-mode optical connectors and jumpers》

5.《YD/T 1636-2007 Fiber to the Home (FTTH) Architecture and General

Requirements》 Fiber Optic Cable Connector Part 4: Sectional Specification

Optical Fiber Optical Cable Mechanical Connector

Application Field

- 1. Applied to open FTTH fiber terminal

- 2. Used in closure boxes, cabinets, terminal boxes, etc.

- 3. Recovery and maintenance of fiber breakage and other accidents

- 4. LAN, WAN, data, and video transmission

- 5. Construction and maintenance of fiber access for end-users

- 6. Fiber entry for mobile base stations

- Optical communication systems, optical instruments, optical fiber CATV, optical fiber sensors.

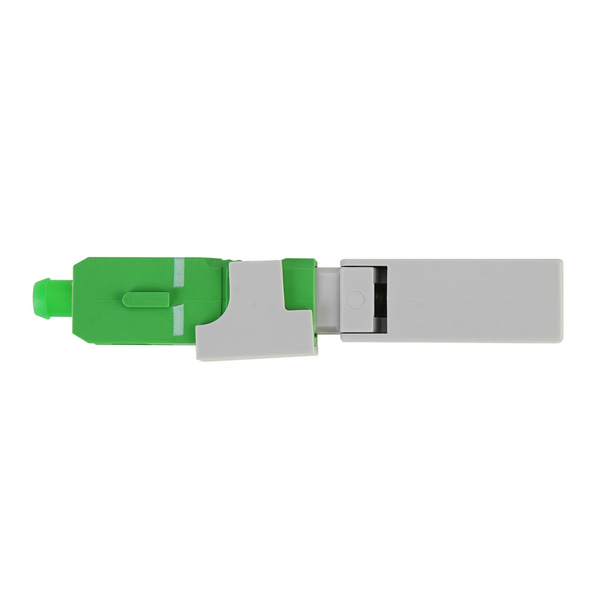

Product Features

- Linkage structure design, when docking with equipment and joints, the reserved microbead remains unchanged;

- Double V-slot structure design, fiber optic docking is stable and reliable;

- The core structure: the use of the normally closed elastic fastening method, excellent technical indicators;

- Applicable optical cable: 2.0mm×3.0mm & 2.0mm×1.6mm butterfly cable;

- Easy to operate, fast construction, high installation success rate, long life cycle, easy maintenance in the later period.

Optical performance parameters

|

Optical Fast Connector Optical Performance |

Unit( dB) |

|||||

|

Code |

Test Item | Mechanical Q/CT 2299-2010-Chapter6.1 | Fusion Splicer Type YD/T 2341.2-2011-Chapter 4.7 |

|||

| Average Value | Maximum Value | Average Value |

Maximum Value |

|||

|

a |

Insertion Loss | ≤0.3 | Tested with standard plugs and adapters:≤0.5 Test with any plug and adapter:≤0.7 |

≤0.25 |

Tested with standard plugs and adapters:≤0.4 |

|

|

b |

Return Loss | ≥40(UPC);≥55(APC) |

≥50(UPC);≥60(APC) |

|||

| Mark1: IL and RL Test at 1310nm. If need to test 1550nm, Please tell us first.

Mark2:IL and RL average and Maximum value make as customer’s requirement. Mark3:Return Loss can customized UPC standard -45~-50dB;APC Standard -55~-60dB |

||||||

Mechanical Character

| Optical Fast Connector mechanical character (Reference to standard Q/CT 2299-2010-6.3) |

Unit( dB) |

|||||

|

ITEM |

Tet Name | Test conditions | Judgement Standard | |||

| Insertion Loss Variation |

Test Result |

|||||

|

|

Mechanical | Fusion Splicer | ||||

| a | Repeatable Assemblability |

Assemblability Times: 5 Times | ≤0.3 | No Requirement |

No mechanical damage, no obvious scratches on the pin surface |

|

|

b |

vibration | frequency: 10-50Hz Sweep frequency:45 Times per minute Amplitude: 0.75mm Single Amplitude Time: Three directors, each 2 hours |

≤0.3 | ≤0.25 |

No mechanical damage, such as deformation, cracking, slack, etc. |

|

|

c |

Drop | Height:1.5meter from sample head Test times: 8 Times |

≤0.3 | ≤0.25 | No mechanical damage, such as deformation, cracking, slack, etc | |

| d | Repeat Plug | Plug Times: 10 | ≤0.3 | ≤0.25 |

No mechanical damage, such as deformation, cracking, slack, etc |

|

|

e |

mechanical Durability |

Plug Times: 500 | ≤0.3 | ≤0.25 | No mechanical damage, such as deformation, cracking, slack, etc | |

| f | Tensile | Telcom Standard Q/CT 2299-2010-7.14: 0.125mm bare fiber: 4N, No online monitoring of Optical performance; 0.25mm fiber type:4N No online monitoring of Optical performance; 0.9mm fiber type:10N online monitoring of Optical performance; Fiber optic cable:20N online monitoring of Optical performance; Fiber optic cable:30N No online monitoring of Optical performance; Time:2 Minute |

≤0.3 | ≤0.25 |

No mechanical damage, such as deformation, cracking, slack, etc |

|

|

j |

Tensile | Communication Standard YD/TT 2341.1-2011-5.15 Load weight:250μm fiber: 4N 900μmFiber: 10N Fiber optic cable 2.0mm and drop cable:20N Fiber optic cable 3.0mm: 50N; Load Time: fiber 30s, fiber optic cable 2min; Load rate: 50N/min<rate The distance between the load point and the mechanical field connector: L=22cm~28cm |

≤0.3 | ≤0.20 |

No mechanical damage, such as deformation, cracking, slack, et |

|

| g | Twist | Load Weight: Fiber Optic cable 15N Rate: 10 Times/Minute times: 200Times |

≤0.3 | ≤0.25 |

No mechanical damage, such as deformation, cracking, slack, et |

|

| Mark 1: Fusion Splicer type can not be repeatable assembly test;

Mark 2:Repeat assembly testing Mainly assesses the deterioration of the amount of insertion loss. Mark 3:After Test, Return Loss Variation≤5dB |

||||||

Working Environment Requirements

|

Item |

||

|

a |

Operating temperature | -40℃ ~+85℃ |

| b | Storage temperature |

-40℃ ~+85℃ |

|

c |

Relative humidity |

≤95%(+30℃ hours) |

| d | Atmospheric pressure |

62kPa~106kPa |

Environmental protection materials

Non-corrosive material, no other harmful effects on human health and other equipment/facilities/cooperating parts.

Material corrosion resistance

All parts of this product’s material are preservatives.

Storage Conditions

well-ventilated, dry, non-corrosive gas or sunlight warehouse,

The indoor temperature is -25℃~+55℃